For centuries, woodworkers have grappled with the inherent instability of their medium. The very organic nature of wood that makes it beautiful – its grain patterns, texture, and warmth – also makes it unpredictable. Nowhere is this challenge more apparent than in delicate inlay work, where different wood species come together in intricate patterns, each piece expanding and contracting at its own rate. Traditional methods of preventing cracks and warping often fell short, especially in environments with fluctuating humidity. However, a recent advancement in wood stabilization technology is revolutionizing the field, offering solutions that were previously unimaginable.

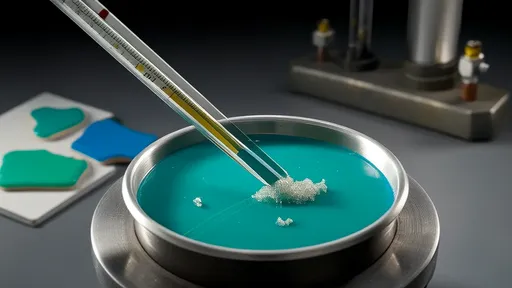

The new process goes far beyond simple resin impregnation techniques that have been used for decades. At its core lies a multi-stage treatment that addresses wood at the cellular level. "We're not just filling voids with resin," explains Dr. Elena Voss, a materials scientist at the Timber Research Institute. "We're actually modifying the wood's hygroscopic properties while maintaining its workability and aesthetic qualities." This nuanced approach represents a significant departure from earlier stabilization methods that often left wood feeling plastic-like or altered its natural appearance.

What makes this breakthrough particularly exciting for inlay specialists is how it handles the interface between different wood species. In traditional inlay work, the differential movement between adjacent pieces creates stress points that inevitably lead to cracks over time. The new stabilization method creates what researchers call a "movement harmony" between disparate woods. While not eliminating expansion and contraction entirely, the process brings the dimensional changes of different species into closer alignment, dramatically reducing the mechanical stresses that cause failure.

The implications for fine woodworking are profound. Marquetry and parquetry, those most delicate of wood arts, stand to benefit enormously. Pieces that once might have been considered too risky for important commissions due to their complex grain structures or inherent instability can now be undertaken with greater confidence. Conservation work too receives a boost, as restorers can stabilize antique inlays without compromising their historical integrity. Early adopters report being able to work with notoriously difficult woods like ebony and rosewood in ways that were previously impossible.

Beyond the technical aspects, there's an artistic dimension to this development. Woodworkers speak of new creative possibilities opening up as the fear of cracking recedes. "It's like being given a broader palette," says master inlay artist Javier Mendez. "I'm experimenting with combinations of woods I would never have dared use together before, knowing they'll remain stable." This artistic liberation may lead to a renaissance in wood inlay design, with more complex patterns and bolder material choices becoming practical options rather than risky experiments.

The commercial implications shouldn't be overlooked either. High-end furniture makers and musical instrument manufacturers, for whom inlay work represents both a value-add and a potential liability, are closely monitoring these developments. The ability to guarantee the longevity of intricate inlay patterns could reshape market expectations and open new design possibilities in these sectors. Early collaborations between researchers and luxury brands have already yielded promising results in prototype pieces.

As with any technological advancement, questions remain about how these stabilized woods will age over decades rather than years. Accelerated aging tests show encouraging results, but only time will tell how the materials behave through generations of seasonal cycles. Traditionalists too raise valid concerns about moving too far from wood's natural characteristics. Yet even skeptics acknowledge that when applied judiciously, these new methods could preserve fine woodwork that might otherwise succumb to the inevitable forces of time and climate.

The wood stabilization breakthrough represents more than just a technical achievement – it's a bridge between tradition and innovation. By solving one of woodworking's most persistent challenges, it allows craftspeople to focus on their art rather than fighting their material. As the technology becomes more refined and accessible, we may look back on this moment as a turning point in the history of wood inlay, when the age-old dream of perfect stability finally became attainable.

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025