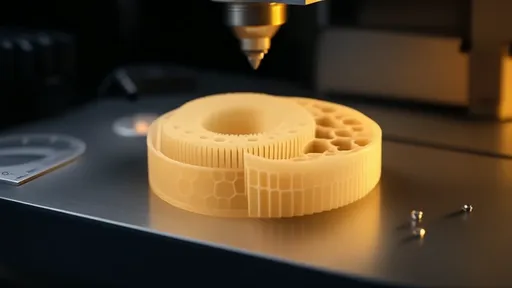

The world of additive manufacturing has reached another milestone with the recent breakthrough in 3D printed wax pattern accuracy. For industries relying on precision investment casting—from aerospace to luxury jewelry—this development marks a significant leap forward. Researchers and engineers have successfully achieved the fabrication of intricate wax patterns with tolerances as tight as 0.1mm, enabling the creation of complex geometries previously deemed unattainable through traditional methods.

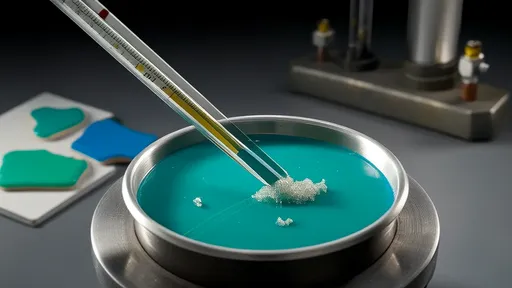

Wax patterns have long been the backbone of investment casting, a process where molten metal is poured into ceramic molds formed around sacrificial wax models. The quality of these wax patterns directly impacts the final metal components. Until now, limitations in pattern precision restricted design freedom and required extensive post-processing. With this new capability, manufacturers can now produce parts with finer details, thinner walls, and more sophisticated internal channels without compromising structural integrity.

The breakthrough stems from advancements in both hardware and material science. High-resolution printers now combine micron-level positioning systems with specialized wax formulations that maintain dimensional stability during printing and subsequent handling. What sets this apart from earlier attempts is the printer's ability to manage thermal contraction—a persistent challenge when working with wax materials. By precisely controlling the cooling process layer by layer, the system prevents warping and maintains the intended geometry within the 0.1mm tolerance window.

Several industries stand to benefit immediately from this technology. In aerospace, turbine blades with intricate cooling channels can now be cast with improved accuracy, potentially enhancing engine efficiency. Medical implant manufacturers gain the ability to create patient-specific devices with biologically inspired microstructures. Even the art world has taken notice, as sculptors explore new frontiers in detailed wax modeling for bronze casting. The jewelry sector, where delicate filigree work often demanded skilled hand-carving, may see the most dramatic transformation as machines replicate these designs with flawless precision.

Material development played an equally crucial role in this achievement. The new generation of printable waxes combines traditional investment casting material properties with additives that improve printability. These hybrid materials maintain the necessary burnout characteristics—complete decomposition without residue—while offering enhanced green strength for handling. The formulations also address another historical limitation: surface finish. Earlier 3D printed wax patterns often required extensive manual polishing to achieve casting-ready surfaces, but the latest materials produce near-net-shape quality straight from the printer.

Process optimization has been another critical factor. Engineers developed specialized support structures that minimize contact points while ensuring stability during printing. These supports dissolve in customized solvents without affecting the primary wax pattern, preserving delicate features. Additionally, the slicing software now accounts for material-specific behaviors, adjusting parameters like nozzle temperature and print speed dynamically based on geometry complexity. This adaptive approach prevents common issues such as nozzle clogging when printing fine details or overhangs.

The implications for supply chains and production timelines are substantial. Traditional wax pattern production often involved multiple steps: machining metal dies, injecting wax, and manual assembly of complex components. The new direct-printing approach eliminates most intermediate steps, reducing lead times from weeks to days. For low-volume production runs or prototype development, this represents both time and cost savings. Perhaps more importantly, it enables rapid design iterations—engineers can test multiple versions of a component without the tooling constraints of conventional methods.

Quality validation processes have also evolved alongside the printing technology. Advanced metrology systems now perform automated inspections comparing printed patterns to digital models at micron resolutions. This closed-loop verification ensures that even the most complex geometries meet specifications before proceeding to mold creation. The integration of machine learning algorithms helps predict potential problem areas in designs, suggesting modifications to optimize both printability and casting outcomes.

Environmental considerations have not been overlooked in this technological advancement. The new wax formulations are derived from renewable sources and designed for complete combustion during burnout, minimizing emissions. Compared to traditional pattern-making that often involved petroleum-based waxes and generated significant waste from machining and mold-making, the additive approach demonstrates improved sustainability. The precision of the process also reduces material usage—complex internal features that previously required assembly of multiple parts can now be printed as single components.

Looking ahead, researchers are exploring even finer resolutions and multi-material wax printing. The ability to incorporate different wax types within a single pattern could enable functional gradations—areas with varying melting points or solubility characteristics. This would open new possibilities for mold design in investment casting. Another promising direction involves combining wax printing with other additive techniques, such as embedding ceramic cores during the build process for even more complex internal geometries.

The 0.1mm precision benchmark represents more than just a technical achievement—it signals a fundamental shift in how precision cast components will be designed and manufactured. As the technology matures and becomes more accessible, we can expect to see its adoption spread across industries where complexity, precision, and speed to market are critical competitive factors. The barriers between digital design and physical realization continue to fall, bringing us closer to a future where manufacturing complexity carries no premium.

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025