The aerospace industry has long been a cradle of technological innovation, pushing the boundaries of materials science to achieve feats once deemed impossible. Among these advancements, titanium's unique properties have made it a darling of aerospace engineers—until now. A groundbreaking development in titanium openwork technology is bridging the gap between aerospace precision and everyday consumer applications, marking a seismic shift in how we perceive this "space-age" metal.

From Fighter Jets to Wristwatches: The Titanium Revolution

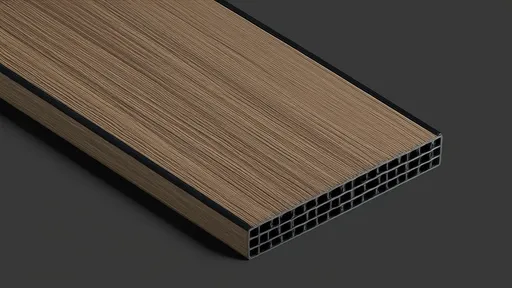

For decades, titanium's high strength-to-weight ratio and corrosion resistance made it indispensable for aircraft frames and spacecraft components. However, the same qualities that thrilled aerospace engineers—its difficulty to machine and high production costs—rendered it impractical for mass-market goods. Recent breakthroughs in subtractive manufacturing and laser etching techniques have shattered these limitations. By borrowing from satellite panel fabrication methods, manufacturers can now create intricate titanium openwork structures with micron-level precision at costs viable for consumer products.

The implications are profound. Luxury watchmakers like Richard Mille have already incorporated aerospace-grade openwork titanium into ultra-light tourbillons, while medical implant companies are testing bone scaffolds with honeycomb structures modeled after rocket fuel filters. "We're not just thinning the material—we're reimagining its very architecture," explains Dr. Elena Voss, a materials scientist at the European Space Agency's technology transfer program. Her team's work on self-supporting titanium meshes, originally designed for Mars rover antennas, now enables bicycle frames weighing less than 800 grams.

The Hidden Physics Behind the Holes

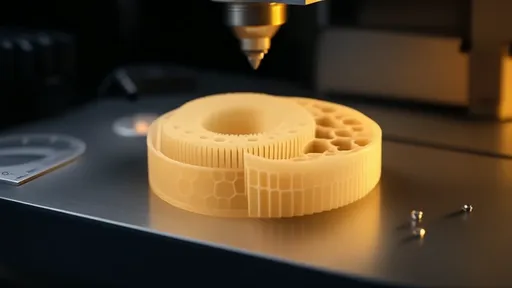

What appears as aesthetic perforations actually represents a triumph of computational design. Borrowing from aircraft "lightening hole" principles—where removing strategic material actually increases structural integrity—the new wave of titanium openwork relies on generative algorithms. These programs, derived from NASA's spacecraft optimization software, calculate stress vectors to determine optimal void placement. The result? Components that maintain 98% of solid titanium's strength while shedding up to 40% in weight.

Sportswear brands have seized this opportunity. A leading running shoe manufacturer recently debuted a midsole with graded openwork density—denser near the heel for impact absorption, more open toward the toes for energy return. This biomimetic approach mirrors the variable porosity found in turbine blades, where different sections endure distinct thermal and mechanical stresses. "It's like giving titanium a skeleton," remarks Tatsuya Yamamoto, whose Osaka-based lab adapted jet engine cooling hole tech for orthopedic applications.

When Less Material Means More Performance

The environmental calculus makes this trend doubly compelling. Traditional titanium machining wastes up to 90% of raw material as chips and shavings. Advanced electrical discharge machining (EDM) methods adapted from satellite production now achieve near-zero waste. Swiss precision instrument maker XYZ has reduced its titanium usage by 65% in diving watches through openwork designs, while maintaining 2000m water resistance. Their patented "load-path lattice" internal structure, inspired by lunar lander shock absorbers, redistributes pressure across micro-arches invisible to the naked eye.

Perhaps most surprisingly, the acoustics of perforated titanium are driving innovation in audio equipment. High-end headphone manufacturers report that specific openwork patterns—originally developed to dampen rocket engine harmonics—eliminate resonance distortions better than solid enclosures. The same physics applies to architectural cladding: a concert hall in Norway features titanium panels whose porosity adjusts to optimize sound reflection based on occupancy levels, using algorithms derived from spacecraft thermal regulation systems.

The Human Factor: Democratizing Space Tech

Beyond performance metrics, this shift represents a philosophical transformation in materials engineering. "We're moving from 'how much material we can add' to 'how intelligently we can remove,'" observes industrial designer Marcus Lee. His studio's titanium eyewear collection employs aircraft spar-inspired openwork hinges that eliminate screws entirely. The frames gain flexibility where needed while maintaining rigidity elsewhere—a principle lifted directly from deployable satellite solar arrays.

As production scales, once-unthinkable applications emerge. Japanese kitchenware brand Tōshu now sells openwork titanium chef's knives that stay sharper longer due to reduced metal fatigue, with handle patterns modeled after satellite fuel tanks for optimal grip. Even the fashion world is embracing the trend: avant-garde designers are laser-cutting titanium threads into breathable, drapeable fabrics that retain shape memory—a technology descendant from spacesuit flexible joints.

The titanium openwork revolution underscores a larger truth: the final frontier's most lasting legacy may not be in the stars, but in how its material innovations reshape our earthly existence. As these microscopic voids multiply across consumer goods, they carry forward aerospace's relentless pursuit of doing more with less—one precisely calculated hole at a time.

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025