The global electronics industry faces mounting pressure to address the environmental impact of electronic waste while recovering valuable materials. As demand for precious metals continues to rise, the establishment of refined standards for recycled precious metal certification from e-waste has become a critical frontier in sustainable manufacturing.

Behind the gleaming surfaces of smartphones and laptops lies an often-overlooked treasure trove. A single metric ton of discarded mobile phones contains approximately 300 grams of gold – significantly higher concentrations than typically found in gold ore. This startling comparison underscores why electronic waste has become known as "urban mines" in recycling circles. The process of extracting and certifying these precious metals, however, remains fraught with technical challenges and regulatory gaps that the industry must urgently address.

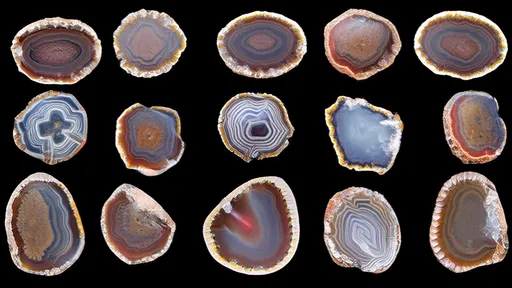

The certification dilemma presents itself at multiple levels. Traditional mining operations have well-established protocols for assaying and certifying metal purity, but recycled materials from complex electronics require entirely different approaches. Unlike uniform ore deposits, e-waste contains an unpredictable cocktail of metals mixed with plastics, ceramics, and hazardous materials. This variability demands sophisticated analytical techniques capable of verifying metal content while accounting for potential contamination.

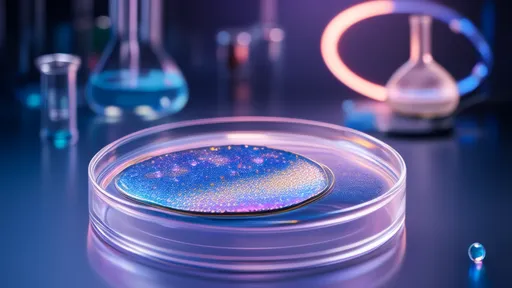

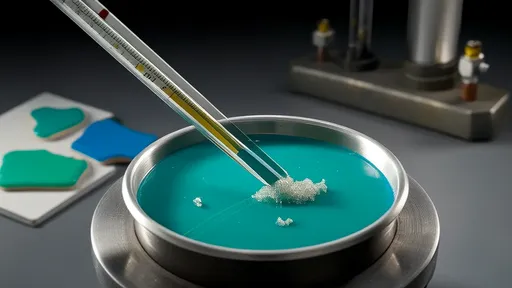

Advanced spectroscopy methods are revolutionizing how recyclers quantify precious metal yields. X-ray fluorescence (XRF) analyzers now provide non-destructive testing that can identify metal compositions within seconds, while inductively coupled plasma (ICP) spectrometry offers unparalleled precision for final certification. These technological advancements enable recyclers to provide documentation that meets the exacting standards of bullion exchanges and industrial buyers.

Environmental accountability has become inseparable from metal certification processes. Leading certification bodies now require full chain-of-custody documentation to verify that recycled metals meet both purity standards and ethical sourcing requirements. This includes auditing energy inputs, chemical handling procedures, and downstream waste management at recycling facilities. The emergence of blockchain-based tracking systems allows permanent, tamper-proof recording of every processing stage from discarded device to purified ingot.

Market dynamics increasingly favor certified recycled metals as manufacturers face stakeholder pressure to improve sustainability metrics. The automotive industry's shift toward electrification has created particularly strong demand for reliably sourced platinum group metals used in catalytic converters and fuel cells. Jewelry manufacturers, traditionally conservative about material sources, now actively promote pieces crafted from certified recycled gold and silver to environmentally conscious consumers.

Standardization efforts face unique regional challenges. The European Union's rigorous WEEE (Waste Electrical and Electronic Equipment) directives contrast with developing nations where informal recycling sectors dominate. Bridging this gap requires international cooperation to establish baseline standards that protect workers and environments while recognizing different infrastructure capabilities. Industry groups like the Responsible Minerals Initiative work to create certification frameworks adaptable to various operational scales.

Laboratory accreditation has emerged as a critical component in certification credibility. Testing facilities must now demonstrate compliance with ISO/IEC 17025 standards for technical competence, employing rigorously trained personnel and maintaining stringent quality control systems. This ensures that certificates of analysis for recycled metals carry the same weight as those for mined materials in commercial transactions.

The chemistry of recovery processes directly impacts certification outcomes. Traditional smelting methods, while effective for bulk processing, often struggle with precise separation of adjacent platinum group metals. Emerging hydrometallurgical techniques promise higher purity yields but require more sophisticated analytical verification. Certification standards must evolve alongside these technological advancements to maintain relevance.

Consumer awareness plays an unexpectedly significant role in driving certification standards. As end-users become more educated about material lifecycles, they demand transparency about the origins of metals in their products. This bottom-up pressure motivates manufacturers to insist on certified recycled content throughout their supply chains, creating a virtuous cycle of improving standards.

The financial sector's growing interest in sustainable investing further elevates the importance of reliable certification. Mining companies with robust recycling operations now attract ESG-focused investors, provided they can demonstrate verifiable standards for recovered materials. This convergence of environmental and financial accountability marks a fundamental shift in how the industry values metal provenance.

Looking ahead, the development of artificial intelligence applications promises to address longstanding certification challenges. Machine learning algorithms trained on vast datasets of material analyses can identify subtle patterns indicating contamination or processing irregularities that might escape human analysts. Such technological integration will likely define the next generation of recycling certification protocols.

Ultimately, the establishment of comprehensive standards for certifying recycled precious metals from e-waste represents more than technical progress—it signifies a philosophical shift in resource utilization. As these standards gain global acceptance, they create the foundation for a circular economy where yesterday's discarded devices become tomorrow's high-tech components without compromising quality or performance. The industry's ability to maintain rigorous, science-based certification will determine whether electronic waste transitions from environmental liability to sustainable resource.

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025

By /Jul 30, 2025