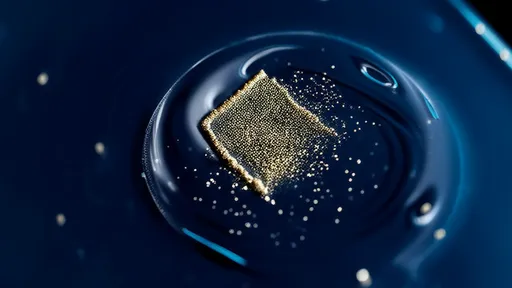

In the world of mechanical engineering, few components are as critical—or as overlooked—as the humble bearing. At the heart of its function lies the seamless rotation enabled by steel balls, tiny spheres that carry immense loads with astonishing precision. The smoothness of this motion is not just a matter of engineering prowess; it’s a symphony of physics, material science, and meticulous craftsmanship.

The magic begins with the steel balls themselves. These are not ordinary spheres; they are crafted to near-perfect roundness, with surface finishes measured in micrometers. Any imperfection, no matter how slight, can disrupt the fluidity of rotation, leading to friction, heat, and eventual failure. The manufacturing process involves grinding, lapping, and polishing, often taking days to achieve the required tolerances. The result is a component so precise that it can spin for hours with minimal resistance.

But precision alone is not enough. The material composition of the steel balls plays a pivotal role. High-carbon chromium steel is the gold standard, offering a balance of hardness and toughness. The balls must withstand constant pressure without deforming, yet remain resilient enough to absorb shocks. Advanced heat treatment processes further enhance these properties, creating a surface that resists wear while maintaining a smooth, low-friction interface.

The interaction between the balls and the bearing races is where the real dance happens. The races, typically made of the same high-grade steel, are machined to exacting profiles. Their curvature must match the balls perfectly to distribute load evenly and minimize stress concentrations. This harmony ensures that the balls roll, rather than slide, reducing friction to a bare minimum. Even the slightest misalignment can disrupt this delicate balance, leading to premature wear or catastrophic failure.

Lubrication is the unsung hero of bearing rotation. Without it, even the most perfectly crafted components would quickly succumb to friction and heat. Greases and oils form a thin film between the balls and races, preventing metal-to-metal contact. The choice of lubricant depends on the operating environment—high-speed applications demand low-viscosity oils, while heavy loads require thicker, more adhesive greases. Modern synthetic lubricants can withstand extreme temperatures and pressures, further extending bearing life.

The applications of these precision components are as diverse as they are essential. From the delicate movements of a wristwatch to the colossal forces in wind turbines, bearings enable motion with efficiency and reliability. In aerospace, they must perform flawlessly under the harshest conditions, where failure is not an option. In automotive systems, they contribute to fuel efficiency by reducing energy losses. Everywhere, the silent, smooth rotation of steel balls is a testament to human ingenuity.

Yet, the quest for perfection never ends. Researchers are exploring new materials, such as ceramics, which offer even lower friction and higher temperature resistance. Advanced coatings, like diamond-like carbon, are being tested to push the limits of durability. Meanwhile, smart bearings embedded with sensors are revolutionizing maintenance, providing real-time data on wear and performance. The future of bearing technology is as dynamic as the rotation it enables.

Behind every spinning wheel, every whirring machine, lies the uncelebrated brilliance of bearing rotation. It’s a world where steel balls, no larger than a pea, carry the weight of industries. Their flawless movement is a quiet marvel, a reminder that sometimes, the smallest things make the biggest difference.

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025

By /Aug 8, 2025